High Voltage Power Cables: The Backbone of Modern Power Transmission

Introduction

Electricity is the driving force of modern civilization. From lighting our homes to powering industries and fueling innovation, reliable energy transmission is essential. To achieve this, high voltage power cables play a critical role. These specialized cables ensure the smooth transfer of electricity over long distances with minimal energy loss.

In India, the demand for reliable energy solutions is growing rapidly. With the rise of industries, smart cities, and renewable energy projects, the need for efficient power cables in India has increased significantly. Alongside heavy-duty transmission lines, there is also rising awareness about electrical wires for home, ensuring both domestic and industrial users get safe and efficient electricity.

What Are High Voltage Power Cables?

High voltage power cables are specialized electrical cables designed to carry electricity at very high voltage levels—generally 33 kV and above. Unlike regular electrical wires for home, these cables are engineered for industrial applications, long-distance transmission, and large-scale power distribution.

Main Components of High Voltage Power Cables

-

Conductor – Usually made from aluminum or copper for high conductivity.

-

Insulation – XLPE (cross-linked polyethylene) or EPR to prevent leakage and ensure safety.

-

Shielding – A metallic layer that protects against electromagnetic interference.

-

Outer Sheath – A protective covering that guards against moisture, chemicals, and mechanical damage.

Importance of High Voltage Power Cables

The significance of high voltage power cables lies in their ability to meet the growing electricity demand across industries, cities, and renewable projects.

-

Efficient Transmission: They carry electricity over long distances with minimal loss.

-

Industrial Dependence: Large industries like steel, cement, and petrochemical plants rely heavily on these cables.

-

Urban Development: Underground power cables in India are increasingly used in smart cities to improve safety and aesthetics.

-

Renewable Energy Integration: Wind and solar projects use these cables to connect generation points to the main grid.

Types of High Voltage Power Cables

Based on Insulation Material

-

XLPE Cables – Popular for thermal resistance, lightweight design, and durability.

-

Oil-Insulated Cables – Used for extremely high voltages, but require careful monitoring.

-

Gas-Insulated Cables – Compact, suitable for dense urban installations.

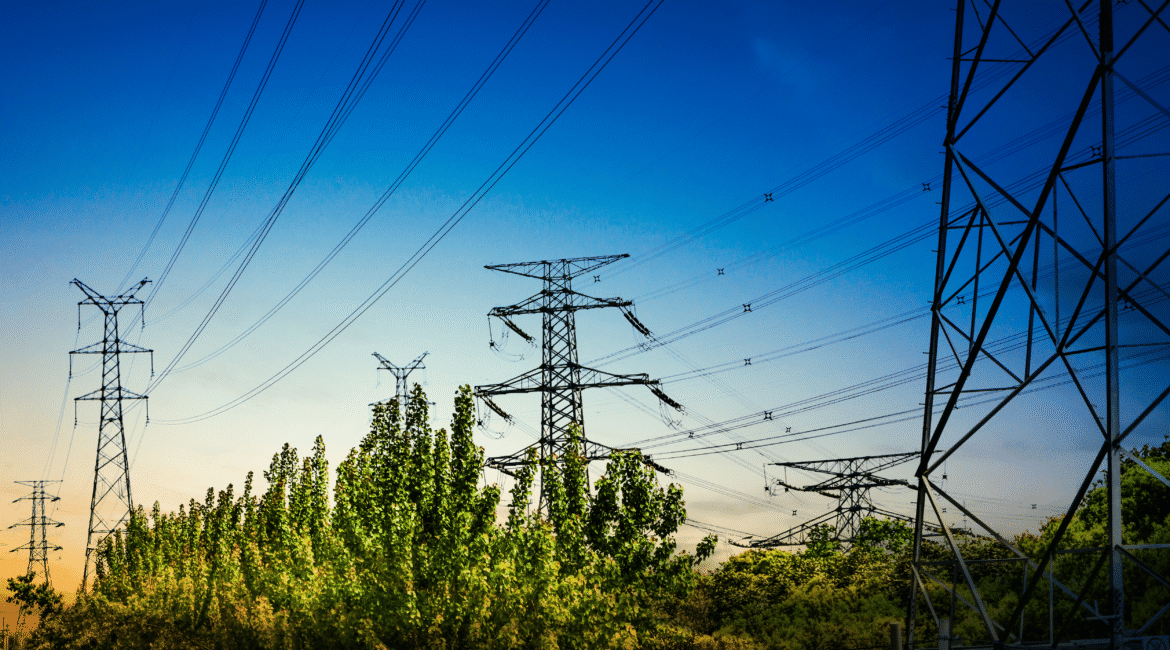

Based on Installation

-

Underground Cables – Preferred in cities for safety and to reduce visual clutter.

-

Overhead Power Cables – More economical, widely used in rural or less populated areas.

Applications of High Voltage Power Cables

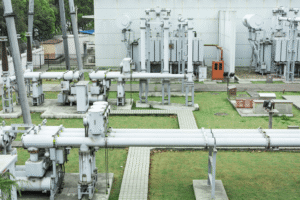

: Power Transmission Networks

They are essential for transmitting electricity from generation plants to substations and distribution grids.

Industrial Operations

Heavy industries require stable and continuous high-voltage supply for operations, which is supported by XLPE and other specialized cables.

Urban and Underground Networks

Smart cities and metro systems in India increasingly prefer underground cables for safe and uninterrupted supply.

Railways and Metro Systems

Railway electrification projects depend on these cables for consistent performance.

Advantages of High Voltage Power Cables

-

Energy Efficiency – Reduced power loss over long distances.

-

Durability – Designed for long lifespans with minimal maintenance.

-

Safety – Insulation reduces risks of fire and electrical accidents.

-

Environment-Friendly – Underground cables reduce visual and environmental impact.

-

Flexibility – Suitable for overhead, underground, and even subsea installations.

Challenges in Using High Voltage Power Cables

-

High Cost of Installation – Especially for underground networks.

-

Difficult Maintenance – Fault detection in underground lines can be time-consuming.

-

Environmental Concerns – Oil-insulated cables may cause leakage risks.

-

Skilled Workforce Requirement – Specialized expertise is essential for installation and maintenance.

High Voltage Power Cables in India

The demand for power cables in India is increasing as infrastructure grows at a rapid pace. From metro rail projects to renewable energy expansion, India is witnessing a transformation in its energy distribution systems.

-

Government Initiatives: Schemes like “Power for All” and renewable integration are driving demand.

-

Urban Development: Underground power grids in cities like Delhi, Mumbai, and Bengaluru rely on high voltage cables.

-

Renewable Energy Growth: With India aiming for 500 GW of renewable energy capacity by 2030, advanced power cables are critical.

At the same time, domestic users are increasingly aware of quality electrical wires for home, ensuring safety and efficiency at the household level.

Innovations in High Voltage Power Cable Technology

-

Smart Monitoring Systems – Real-time monitoring for early fault detection.

-

Eco-Friendly Insulation – Replacing oil-based insulation with XLPE and other recyclable materials.

-

Superconducting Cables – Offering almost zero resistance, still under research but promising.

-

High-Temperature Cables – Designed for industries operating under extreme heat.

Best Practices for Installing High Voltage Power Cables

-

Correct Cable Selection – Match cable type with application requirements.

-

Proper Installation Techniques – For underground cables, trenching and protective ducts are essential.

-

Routine Maintenance – Conduct insulation resistance and thermal analysis.

-

Compliance with Standards – Follow national and international safety regulations.electricity high voltage pole and sky

Future of High Voltage Power Cables

With India’s energy transition toward renewables and smart grids, the future of high voltage power cables looks promising. Eco-friendly insulation, digital monitoring, and smart-grid compatibility will redefine efficiency and sustainability.

For households, the use of certified electrical wires for home will remain vital for safety, while large-scale industries and cities continue to depend on advanced power cables for uninterrupted supply.

Frequently Asked Questions (FAQs)

Q1: What voltage qualifies as high voltage?

High voltage typically refers to systems above 33 kV. Transmission lines can go up to 400 kV or more.

Q2: Are XLPE cables better than oil-insulated cables?

Yes, XLPE cables are lighter, more durable, and environmentally friendly compared to oil-insulated alternatives.

Q3: Why are underground cables used in cities?

Underground power cables in India improve safety, reduce outages due to weather, and enhance aesthetics in urban areas.

Q4: What is the lifespan of high voltage power cables?

With proper maintenance, they can last 30–50 years.

Q5: How do high voltage cables differ from electrical wires for home?

High voltage cables are built for industrial and large-scale applications, while electrical wires for home are designed for domestic low-voltage supply.

Conclusion

High voltage power cables are the foundation of modern energy distribution, ensuring reliable, efficient, and safe transmission of electricity. From industrial plants to metro cities and renewable projects, these cables support the backbone of progress.

In India, the growing need for quality power cables in India and safe electrical wires for home highlights the importance of investing in reliable, future-ready cable solutions. As technology advances, smart and eco-friendly cables will shape the future of sustainable power transmission worldwide.

Bhagyadeep Cables-high voltage power cables – Adseon

[…] just manufacture wires; we engineer the critical lifelines that sustain modern industries. Our high voltage power cables are the result of three decades of unwavering dedication to a “Zero Defect” philosophy, […]

Bhagyadeep Cables-high voltage power cables – All Biz

[…] just manufacture wires; we engineer the critical lifelines that sustain modern industries. Our high voltage power cables are the result of three decades of unwavering dedication to a “Zero Defect” philosophy, […]

Bhagyadeep Cables-high voltage power cables – Biz City

[…] just manufacture wires; we engineer the critical lifelines that sustain modern industries. Our high voltage power cables are the result of three decades of unwavering dedication to a “Zero Defect” philosophy, […]